Building Darth Vader's lightsaber

This is one of those things everyone should do. Everyone should own a lightsaber, and everyone should -- ideally -- build it themselves. This is my version of Darth Vader's lightsaber, built from PVC tube and various bits of junk.

Enjoy.

Step 1: Search internet for blueprints and dimensions. This is not difficult. I'd suggest searching for something like "darth vader lightsaber dimensions", or such. Use your imagination.

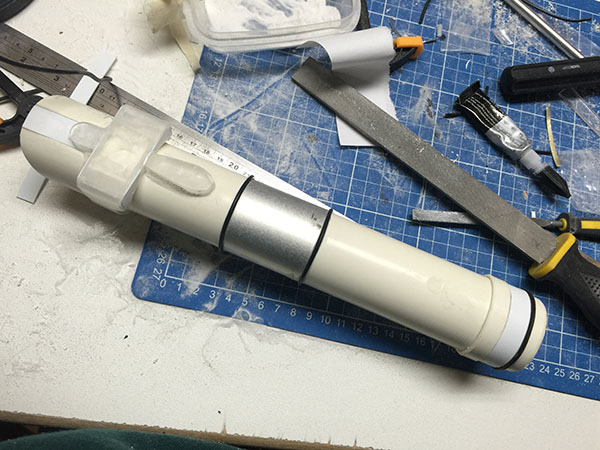

Step 2: Figure out your scale, if you need to. I have PVC tube in 42mm, which is awfully close to the 40mm barrel the original Graflex-style hilt was built with, so I'm pretty content to go with that, and I chose not to adjust any of the other dimensions, as two millimetres didn't seem enough to bother with.

Step 3: Cut the tube to the right size and cut the end off at the appropriate angle. A mitre box, or a mitre saw/drop saw/compound saw/whatever would probably be cool for this. I didn't have any of these things handy, so I just marked the end and hacked it off with a hacksaw with plenty of plastic to spare and set about filing it down to the correct marks.

Step 4: Vader's saber has an extra-thick cowling around the emitter with a rectangular box on the side. I made the thicker cowling by adding an extra piece of 42mm PVC tube around the outside of the main tube.

Again, I knew I would make a total balls-up of the angled cut, so I hacked it off with some PVC to spare and filed it down to make a "machined" edge. There you go, a double-thickness cowling.

Step whatever: There's an additional band at the base of the cowling, which is thicker again. Same process. This bit requires an extra part cut out, as it flares toward the switch side of the saber.

File it.

Cut out said bit, and you've got the beginnings of a saber emitter cowling.

Step orange: The various layers and thicknesses of PVC create some pretty ugly gaps. Only one of these needs to be fixed with any real quality, the rest will get covered up by the rectangular box contraption we're about to build.

Step orange: The various layers and thicknesses of PVC create some pretty ugly gaps. Only one of these needs to be fixed with any real quality, the rest will get covered up by the rectangular box contraption we're about to build.

This is clear acrylic. Clear acrylic is awesome. It's awesome for a bunch of reasons:

- It's easy to get it to the right size, you can just score-and-snap the stuff

- It sands beautifully

- You can drill and dremel the bollocks out of it, because it doesn't melt or burn until it gets to surface-of-the-sun temperatures

To make the rectangular box on the cowling, I layered various bits of acrylic and styrene, and did some incredibly rough filling.

Another piece of acrylic, this one measured to be the diameter of the triple-layered PVC tube it's sitting on top of. It should be exactly the width of the tube. This is important. Kind of.

Join the whole thing together, and fill and sand until it doesn't look like crap. What I've done here is pretty much make a box, using scrap acrylic and some odds and ends of styrene sheet. I like using styrene sheet for the parts that don't necessarily need to hold much weight, or are only decorative. It's thin, but it looks solid when it's all painted and good to go. My adhesive of choice for this project is super glue, and lots of it. Super glue can be accelerated by using bicarbonate of soda, which:

- sets the glue instantly

- sets itself instantly, and very much like a rock

- can be built upon in layers to fill space

- can be sanded to a very nice finish

- generally fills flush with any surface

It's essentially magic and witchcraft. And it's awesome.

Step parsnip: Make rectangular box look decent. My approach to this is to add layers, then sand back, then add layers, then sand back. Superglue and bicarbonate of soda is pretty much the undo button of sculpting and carving stuff like this. Screw it up? Add more. Too much? Sand it away. Just don't breathe the fumes or stick any important parts of your body to things you don't want them stuck to.

Here I've also filled the channel at the top, where the cowling tube splits apart. 1mm styrene sheet and some superglue and baking soda. Perfect.

Sanded and pretty much finished.

Step squeeble: This is three layers of acrylic glued together in a vice, getting filed down to be the little control panel on the top of the saber.

Step 1,493: Build control box and clamp details. The clamp strip is a piece of sheet metal from a clothes dryer duct, which happens to be awesome for lightsaber clamps. This is why you should never throw away anything that looks like it could be useful.

I didn't document building the control box, as the process was pretty much:

- cut rectangles

- glue together

- attach to saber

The ends of the clamp strap are detailed with some AV wiring. This is sometimes a mistake, as some kinds of paint make the rubber insulation on electrical wiring sticky, and they never stop being sticky. In this case, I appear to have dodged a bullet, and the wires remain stick-free.

Progress so far, and a messy work area. I've used similar techniques to build the end cap on the other end -- cut and split some PVC tube, add detail using styrene, and a piece of AV wiring for the rounded detail.

Progress so far, and a messy work area. I've used similar techniques to build the end cap on the other end -- cut and split some PVC tube, add detail using styrene, and a piece of AV wiring for the rounded detail.

Step weasel: A coat of primer usually identifies all of your flaws. There are some chunks in the PVC pipe that will need filling and sanding. Here, I've cut two out of the six vent holes in the casing. I ultimately decided to only cut four -- two on each side -- as I was happy with how the outer four holes looked, and I had some concerns that I would not get the inside two holes perfectly aligned. I'd prefer it looks properly made and inaccurate than accurate with flawed construction. Things like that annoy me.

Step SILVER: Chrome the hell out of it. Here, I've coated it with a liberal lashing of Krylon classic chrome, and am in the process of masking out the black parts to be hit with some glossy black.

Step BLACK: Here's the black. I made the executive decision to make it a fairly thick coat of black, as the paint that I have tends to decide on its matte level based on how thick the coat of paint is, and I wanted this to be as glossy as possible. If you take this stupid approach, be sure to hold the painted object by hand and move it around a lot, so any drips don't kind of well up in the low points and screw the paint job entirely. After much gyrating and swearing, the paint finally dried enough to put the thing down.

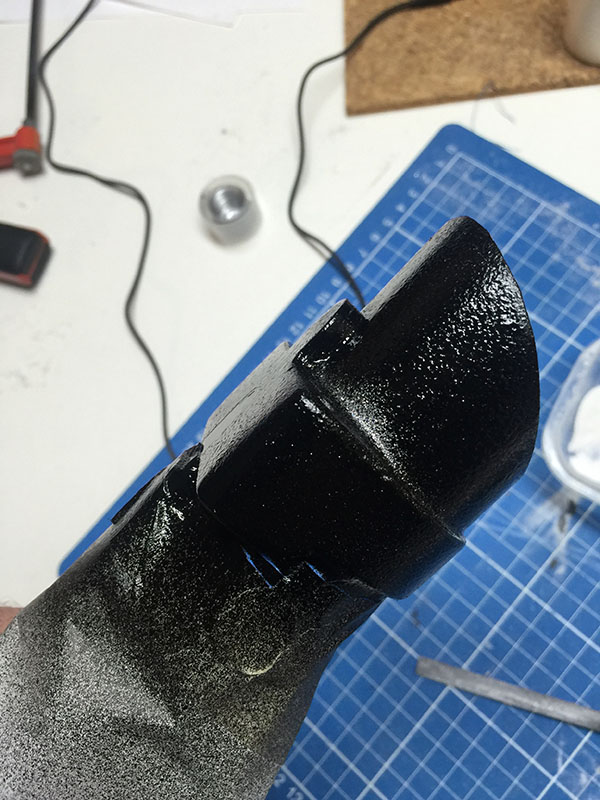

Step Gary Glitter: Now we're getting risky. I knew Darth Vader's saber had a weird kind of cast-iron effect on the emitter cowling. It's lumpy, and very, very matte black. I originally planned to use granite-effect spray paint to achieve this, but the stuff is expensive and I didn't want to waste money on something that might not work. So I wasted less money on something that might not work.

Step Gary Glitter: Now we're getting risky. I knew Darth Vader's saber had a weird kind of cast-iron effect on the emitter cowling. It's lumpy, and very, very matte black. I originally planned to use granite-effect spray paint to achieve this, but the stuff is expensive and I didn't want to waste money on something that might not work. So I wasted less money on something that might not work.

For half the price of the granite paint, I managed to find some glitter paint, which also imparts a texture to whatever you paint with it. Turns out the vile shite is just particles of glitter suspended in clear varnish, which, when sprayed, spit in all directions like a hurricane of shiny snowflakes and proceed to stick to everything. Given that glitter has a propensity for sticking to everything when it's in its natural state, this combination is truly terrifying.

Regardless, I masked off the end of the saber and coated it three times in Rustoleum glitter paint.

GLITTER.

Step farfalarganfarful: While waiting for the umpteen coats of craft herpes to dry, I started building the emitter's internals. These did not turn out as detailed as I had hoped, as I was a) impatient, and b) running out of useful parts. I ended up making a wee cylinder to stuff down the end, by cutting some PVC tube and splitting it so I could reduce its diameter, then cutting a disc of acrylic to go in the end. The detail on the emitter is a smaller piece of PVC tube, and the end of a wall plug. High tech.

The ring should really be larger, but it's all I had lying around, and I usually have zero patience when a project is nearing completion. You can see the end of the saber hilt in the above image, too. I added an additional strip of corrugated styrene to the very end, giving a kind of grip-like appearance to the endcap. It looks awesome drowned in chrome paint. (Lets face it, everything looks awesome drowned in chrome paint.)

Step flurple: This is the switch, which is made from three pieces of acrylic glued together and clamped, then filed within an inch of its life until it resembled the switch from Vader's lightsaber. I drilled the 4mm hole starting with a .5mm bit in my Dremel and progressively scaling up the bits, so that I could be reasonably sure the drill wouldn't wander and end up making a stupidly off-centre hole, or something. One of acrylic's best features is that it drills really, really nicely.

Primer on the switch. Yes, there's a gouge in it. No, I don't care. Life's too short for that kind of thing.

Step eleventy squillion: Details to go on top of the saber. The plastic shape is styrene, designed to fit over the acrylic extrusion I made earlier. On top of it is a washer and a screw, the head of the screw is filled in with superglue and sodium bicarbonate so that it doesn't look like a screw anymore. The bugle-headed plasterboard screw will substitute for the flanged....dial....thing...on the top of the saber. It's kind of the right shape. I'm getting impatient, here. I ended up sticking a washer on top of the bugle-headed screw and filling the washer's hole with superglue and soda, just to disguise it obviously being a plasterboard screw.

Step eleventy squillion: Details to go on top of the saber. The plastic shape is styrene, designed to fit over the acrylic extrusion I made earlier. On top of it is a washer and a screw, the head of the screw is filled in with superglue and sodium bicarbonate so that it doesn't look like a screw anymore. The bugle-headed plasterboard screw will substitute for the flanged....dial....thing...on the top of the saber. It's kind of the right shape. I'm getting impatient, here. I ended up sticking a washer on top of the bugle-headed screw and filling the washer's hole with superglue and soda, just to disguise it obviously being a plasterboard screw.

Step boo-urns: One of many coats of super-flat black spraypaint on the saber cowling. The texture from the glitter paint shows through quite nicely.

This is starting to look a bit like a lightsaber. The emitter is now in place. I've also built some grips for the handle. They're nothing elaborate -- flat pieces of acrylic, some with the edges smoothed out, some with some angular corners. I didn't take photos of the process. I'm sorry.

This is starting to look a bit like a lightsaber. The emitter is now in place. I've also built some grips for the handle. They're nothing elaborate -- flat pieces of acrylic, some with the edges smoothed out, some with some angular corners. I didn't take photos of the process. I'm sorry.

At some point, I've also put some flat pieces of Styrene painted with Krylon classic chrome on the sides of the control box.

Step AHOOGAH, AHOOGAH: Some more details. The knobs-and-buttons thing makes a re-appearance, this time with paint. I thought I'd made a tragic mistake by painting the bizarre styrene shape with spray paint (and primer), because it started to eat the styrene and the whole thing ended up turning to glue, but something weirdly fortuitous happened: It just rounded the edges off perfectly, leaving a really nice gloss finish. So, uh, yay. Or oops. Depending on how you look at it.

Bottom bit is a washer with the head of an upholstery nail attached.

Washer/nail combo ended up on the side of the control box, here, where it serves some purpose best known to the Empire.

Washer/nail combo ended up on the side of the control box, here, where it serves some purpose best known to the Empire.

Step doobly-doo: The small bolt/knob at the end doesn't look a great deal like the original, but it does the job. For this, I used a piece of acrylic rod from a paintbrush handle and lathed it in a drill with a rounded file to create the shape. I didn't document this process as I was concerned that I could die if I was distracted whilst lathing a piece of plastic wedged in a drill, wedged in a vice. Perhaps next time.

The finished product. A reasonably accurate version of Darth Vader's lightsaber. It now lives in a cabinet along with a bunch of other junk.

Hooray!